Single Phase or 3 Phase Reliable Supplier Fish Shrimp Aerator Oxygen Machine Paddle Wheel Aerator for Aquaculture

Basic Info

| Model NO. | SC |

| Type | Farming Machinery |

| Working Method | Friction Type |

| Power Source | Electric |

| Certification | CE |

| Condition | New |

| Phase | 3 Phase / 1phase |

| Power | 1HP/2HP/3HP/4HP/5HP/6HP/12HP |

| Use | Aquculture |

| Frequency | 50Hz/60Hz |

| Keywords | Paddle Wheel Aerator |

| Float | HDPE |

| Impeller | PP |

| Frame | 201/304#Ss |

| Shaft | Soild /Hollow |

| Motor | 4/9spline |

| Gearbox | Iron /Plastic |

| Origin | China |

| HS Code | 8479899990 |

Product Description

Product DescriptionWhen the motor starts running, impellers will rotate and touche water surface, it will press air into water and therefore increase some oxygen in water.

The most importance is working impellers can make sufficient water splash and strong water current. Large amount of splash will take air into water and enrich obviously dissolved oxygen in water. Meantime, water waves and current will eliminate harmful substances like ammounia, nitrite, hydrogen sulfide, etc out of water and finally clean water.

All brand new materials produced components to make sure our customers receive high quality items. It can be used both on freshwater and seawater.

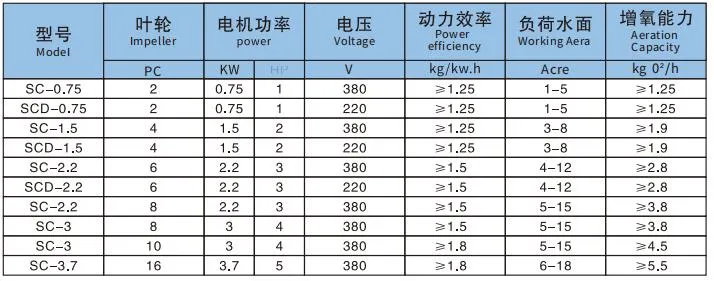

Product Parameters

Q1. What's your company's main products?

A: Our company is specialized in many kinds of fish pond aerators,including Paddle wheel aerator,Floating aerator,Surge aerator, Wave aerator and Jet aerator. Can be working with DC/AC or solar system motor.Q2. What's your payment term?

A: 30% T/T in deposit, the rest against on the copy of B/L.Q3. What's the MOQ for your production?

A: The MOQ is 10 pcs or depends on your products requirements.Q4. Is it all right to make customer's own brand name?

A: OEM is ok.Q5. Where is your loading port?

A: Ningbo/Shanghai, China or else port as your request.

1. Start production as soon as receiving down payment.

2. Send photos of machine in manufacturing and finished photos to client, for your better learn about the machine's condition.

3. Delivery machine in time, taking photos during loading, so you can "remote monitoring"

your goods.

4. Documents and certificate available in time.

5. Manual documents available. Engineer can be sent to client site for installation instruction.